Why Are Stainless Hex Nuts Essential for Fastening Projects?

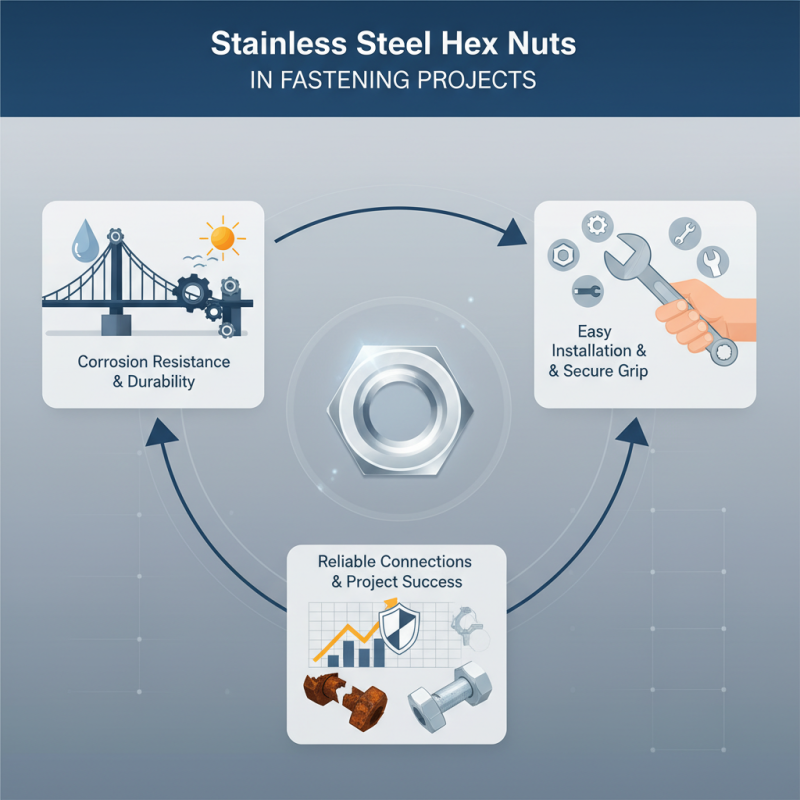

Stainless Hex Nuts play a crucial role in various fastening projects. These small yet powerful components provide reliable connections in numerous applications. From construction to automotive manufacturing, their strength and durability are unmatched.

Essentially, Stainless Hex Nuts resist corrosion, ensuring that assemblies remain intact even in harsh conditions. Their hexagonal design allows for easy gripping, facilitating installation with standard tools. Quality matters; not all nuts are created equal. Using subpar materials can lead to failures at critical moments.

In our fast-paced world, overlooking these essentials can result in costly mistakes. Some projects fail because of improper fastening solutions. Thus, investing in high-quality Stainless Hex Nuts is not just wise; it’s necessary. Conducting careful research can elevate project success.

The Importance of Stainless Hex Nuts in Fastening Applications

Stainless hex nuts play a crucial role in fastening applications. Their resistance to corrosion makes them ideal for various environments. According to industry reports, around 70% of mechanical failures in construction can be attributed to poor fastening systems. Stainless hex nuts help mitigate these failures significantly.

In marine and outdoor settings, stainless hex nuts are vital. They withstand harsh conditions without losing integrity. Research indicates that stainless steel, specifically Type 316, offers superior protection against saltwater and humidity. This durability is essential in maintaining the safety and longevity of structures.

However, not all stainless hex nuts are equal. Some low-cost alternatives may compromise strength and quality. Users often overlook this aspect, leading to costly repairs. For optimal performance, understanding material grades is essential. Investing in high-quality stainless hex nuts can prevent future issues, illustrating the importance of proper selection in fastening applications.

Key Characteristics of Stainless Steel Hex Nuts

Stainless steel hex nuts are vital for various fastening projects. These nuts provide durability and resistance to corrosion. Made from stainless steel, they remain functional even in challenging environments. This quality makes them ideal for outdoor applications. When securing structures, reliability is important. Rust and degradation can lead to failure. Using stainless steel hex nuts minimizes these risks.

In addition to corrosion resistance, these nuts offer a strong grip. Their hexagonal shape allows for easy tightening with tools. This feature provides efficiency during installation. However, it's essential to ensure proper torque. Over-tightening can lead to stripping. Stripping damages the nut and bolt, leading to future issues. It’s a mistake that can cause delays in projects.

Moreover, aesthetic appeal can be a consideration. Stainless steel has a shiny, polished surface. This feature can enhance the look of visible fasteners. Yet, this may not be a priority for all projects. Balancing functionality with aesthetics requires thought. Each project may prioritize different factors. Understanding these characteristics helps in making informed choices.

Advantages of Using Stainless Hex Nuts in Various Environments

Stainless hex nuts are crucial in various fastening projects. Their resistance to corrosion makes them ideal for outdoor applications. In environments with moisture or chemicals, these nuts maintain integrity over time. They won’t rust easily, even when exposed to harsh elements. This durability saves time and money in maintenance and replacements.

Another key advantage is their versatility. Stainless hex nuts can be used in construction, automotive, and more. They can withstand high temperatures, making them suitable for different conditions. While they offer many benefits, it is essential to ensure proper installation. Mismatched sizes can lead to weak connections. In some cases, even stainless steel can corrode if not paired correctly with compatible materials.

The aesthetic appeal of stainless hex nuts cannot be overlooked. Their shiny finish adds a polished touch to projects. However, their appearance can diminish if exposed to certain environmental conditions. Choosing the right ones for each project is sometimes challenging. Careful consideration is needed to achieve optimal performance.

Common Industries That Utilize Stainless Hex Nuts

Stainless hex nuts are crucial in a variety of industries. The automotive sector relies heavily on these components for assembling engines and chassis. According to a report from the Automotive Industry Action Group (AIAG), approximately 80% of fasteners used in vehicles are made from stainless steel. This enhances durability and resistance to corrosion.

In construction, stainless hex nuts are vital for securing structural elements. The American Institute of Steel Construction (AISC) recommends using stainless steel fasteners in environments prone to corrosion. This includes coastal areas, where salty air can degrade other materials. Moreover, a study from the National Association of Home Builders (NAHB) highlights that homes built with stainless components can last significantly longer, reducing the need for frequent repairs.

The aerospace industry also prioritizes stainless hex nuts. They ensure safety in every flight operation. A recent FAA report emphasizes that over 90% of the fasteners used in aircraft are stainless steel. This choice minimizes weight while providing strength. Despite their benefits, the challenge remains: costs can be higher compared to other materials. Companies must weigh these factors for specific applications.

Best Practices for Selecting and Installing Stainless Hex Nuts

When selecting stainless hex nuts for fastening projects, consider material quality. AISI 304 stainless steel is common due to its excellent corrosion resistance. According to industry data, 70% of construction projects use this material. It provides strength and durability. In contrast, AISI 316, with added molybdenum, suits environments with higher salt exposure. This decision impacts longevity.

Installation of stainless hex nuts also requires attention. Clean surfaces ensure a tight fit. Dirty threads can compromise grip strength. Reports indicate that improper installation leads to a 30% risk of joint failure. Using a torque wrench can help maintain consistent pressure. Over-tightening is a common mistake, risking damage to both the nut and bolt.

Be mindful of environmental conditions too. Temperature fluctuations can affect material performance. Always check for compatibility with other materials used in assembly. Adjusting your selection based on specific project needs is crucial. Ignoring these details can lead to costly repairs later.