How to Select the Right Valve Control Valve for Your Industrial Application

In the intricate landscape of industrial applications, selecting the appropriate Valve Control Valve is paramount for ensuring optimal performance and efficiency. According to a report by MarketsandMarkets, the global valve control market is projected to grow from USD 13.8 billion in 2020 to USD 20.1 billion by 2025, with a compound annual growth rate (CAGR) of 8.3%. This growth underscores the critical role that valve control plays in various sectors, including oil and gas, water and wastewater management, and chemical processing. As industries face increasing pressure to enhance operational reliability and energy efficiency, understanding the specific requirements and functionalities of different valve control options becomes essential. By carefully assessing factors such as flow requirements, pressure ratings, and automation capabilities, industrial engineers can ensure that they choose a Valve Control Valve that not only meets regulatory standards but also aligns with their long-term operational goals.

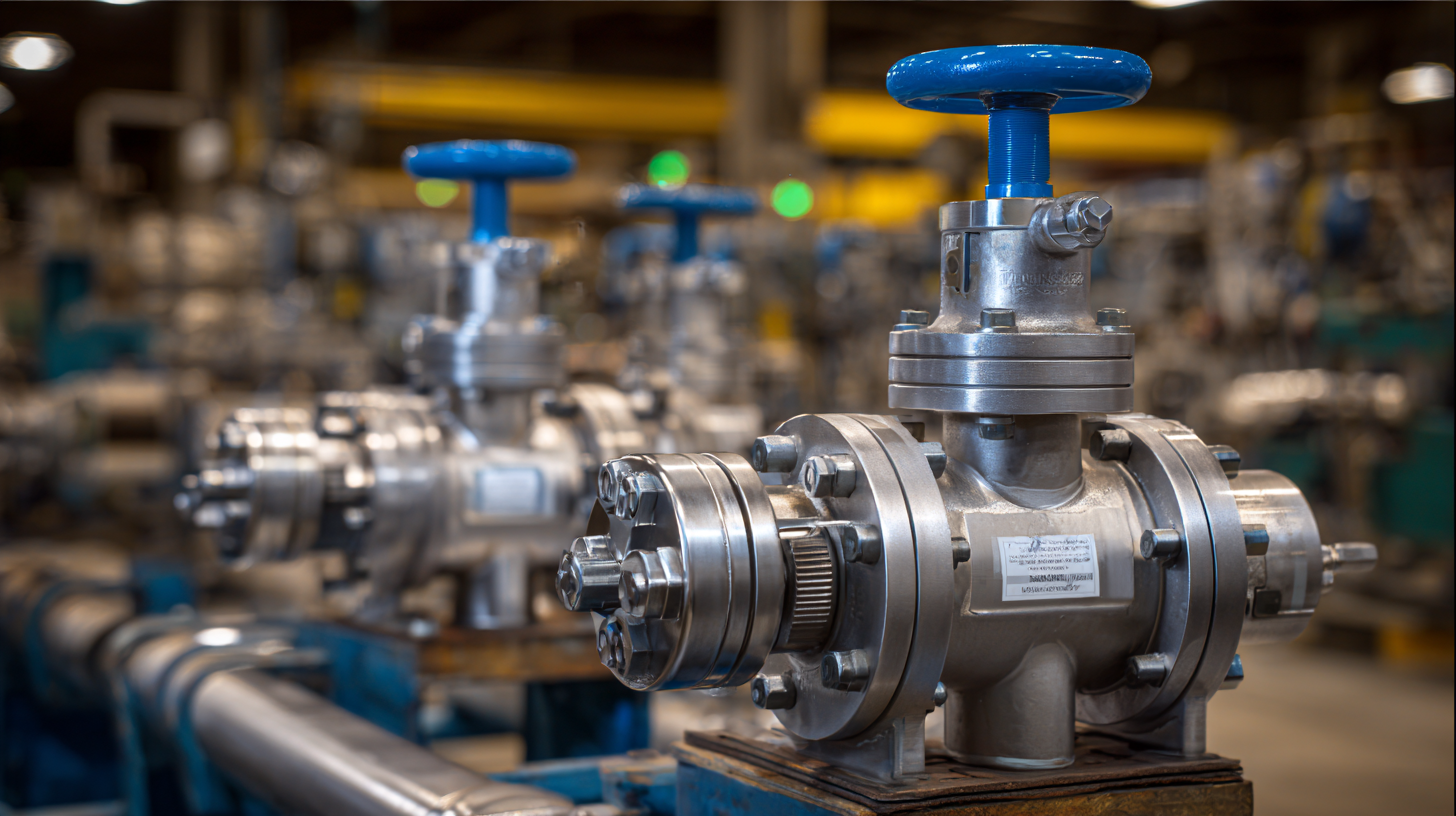

Understanding the Basics of Control Valves in Industrial Applications

Control valves play a crucial role in managing the flow of fluids in various industrial applications. Understanding the fundamentals of how these valves operate is essential for selecting the right one for a specific process. Generally, control valves regulate the flow rate, pressure, and temperature within a system, ensuring optimal performance and safety. These valves can be categorized into several types, such as globe valves, ball valves, and butterfly valves, each designed for particular functions and conditions. Familiarity with the basic operating principles, including the relationship between valve position and flow rate, is critical for effective application.

Control valves play a crucial role in managing the flow of fluids in various industrial applications. Understanding the fundamentals of how these valves operate is essential for selecting the right one for a specific process. Generally, control valves regulate the flow rate, pressure, and temperature within a system, ensuring optimal performance and safety. These valves can be categorized into several types, such as globe valves, ball valves, and butterfly valves, each designed for particular functions and conditions. Familiarity with the basic operating principles, including the relationship between valve position and flow rate, is critical for effective application.

In addition to the types of valves, knowing the key components that make up control valves is vital. These include actuators, which determine the valve's positioning, and positioners that enhance the valve's accuracy in responding to control signals. The materials used in valve construction are also important as they need to withstand specific environmental conditions such as temperature extremes and corrosive substances. By grasping these basic principles and component functions, industrial operators can make informed decisions when selecting control valves tailored to their unique application needs.

Identifying the Key Requirements for Your Specific Application

When selecting the right control valve for an industrial application, it's crucial to identify the specific requirements of your process. Factors such as fluid characteristics, flow rate, and pressure drops play a significant role in determining the suitable valve type. For example, a report from the Control Valve Market Analysis indicated that nearly 60% of control valve failures are linked to incorrect selection based on application needs. Understanding these parameters will help ensure operational efficiency and longevity of the system.

**Tips:** Always conduct a thorough fluid analysis. The viscosity, temperature, and corrosiveness of the fluid can significantly impact the choice of materials and valve designs. Moreover, it's important to consider the actuator type. Electric actuators offer quick response times, while pneumatic ones generally provide greater force, adaptable for varying applications.

Another essential consideration is the control strategy required for your system. Whether a simple on-off control or complex PID regulation, knowing your control strategy will help identify the best valve configuration. According to a report by the International Society of Automation, the right control strategy can improve system efficiency by up to 25%. Tailoring the valve selection to your process requirements leads to improved performance and reduced operational costs.

Valve Control Types in Industrial Applications

This bar chart illustrates the usage frequency of various valve control types in industrial applications. The data shows that Ball Valves are the most frequently used, followed by Globe Valves and Butterly Valves.

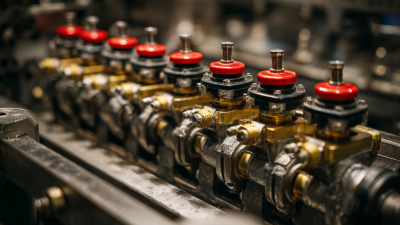

Evaluating Different Types of Control Valves Available in the Market

When selecting a control valve for an industrial application, it is crucial to evaluate the various types available in the market. The most common control valves include globe valves, ball valves, plug valves, and butterfly valves, each designed for specific applications and performance characteristics. According to a recent report by MarketsandMarkets, the global control valve market is projected to grow from USD 9.2 billion in 2020 to USD 12.6 billion by 2025, indicating a robust demand for efficient flow control solutions.

Globe valves are favored for throttling applications due to their ability to manage flow rates effectively. In contrast, ball valves offer a quick on/off control and are widely used in applications requiring tight shut-off. It’s important to assess factors such as the valve size, pressure rating, and material compatibility with the fluid being handled.

**Tip:** Always consult the valve manufacturer’s data sheets for detailed specifications and performance curves to ensure the selected valve meets your operational requirements.

Additionally, consider the control valve's actuation method. Electric actuators are ideal for remote control applications, while pneumatic actuators are often preferred for faster response times. The selection process should align with both your technical needs and operational efficiency goals.

**Tip:** Conducting a thorough cost-benefit analysis of different valve types can provide insight into which option offers the best long-term value for your specific application.

Assessing Material Compatibility and Environmental Considerations

When selecting a control valve for your industrial application, assessing material compatibility is crucial. Different materials react to various fluids and environmental conditions, which can lead to premature failure or inefficiency. For instance, corrosive substances may require valves made from stainless steel or specialized alloys. Understanding the physical and chemical properties of the fluids handled, including temperature and pressure, helps in determining the best materials for longevity and reliability.

Tips: Always refer to the valve manufacturer’s compatibility charts to ensure the selected materials will withstand the specific conditions of your application. Additionally, consider potential environmental factors such as temperature fluctuations and exposure to harsh chemicals or atmospheric elements that can influence material choice.

Environmental considerations also play a significant role in valve selection. Assess the operational environment to identify any potential hazards, such as exposure to moisture or extreme temperatures, which can affect valve performance. Opt for valves with protective coatings or those designed for adverse conditions to enhance their operation and lifespan.

Tips: Conduct regular inspections and maintenance to identify signs of wear early. This proactive approach can help mitigate issues caused by environmental factors, ensuring smooth operations in your facility.

Making an Informed Decision: Cost, Maintenance, and Performance Factors

When selecting the right control valve for industrial applications, decision-makers must carefully consider cost, maintenance, and performance factors. According to the Control Valve Market Report by Research and Markets, the global control valve market is projected to reach $10.3 billion by 2026, driven largely by the rising demand in sectors like oil and gas, water and wastewater management, and pharmaceuticals. This underscores the need for organizations to invest in quality control valves that meet both operational and budgetary requirements.

Maintenance is another critical factor in valve selection. A study published by the Journal of Applied Mechanical Engineering highlights that improper valve maintenance can lead to a 20-30% increase in overall operational costs. Organizations should evaluate the maintenance protocols of potential valves, ensuring that they include easy access for repairs and a design that minimizes wear. Additionally, performance metrics such as flow capacity, pressure drop, and responsiveness under varying conditions can significantly impact the operational efficiency of an industrial setup. Utilizing valves with proven performance data can lead to enhanced productivity and reduced downtime, reinforcing the importance of thorough research in the selection process.

How to Select the Right Control Valve for Your Industrial Application

| Valve Type | Cost ($) | Maintenance Frequency (Months) | Performance Rating | Suitable Applications |

|---|---|---|---|---|

| Globe Valve | 150 | 12 | High | Oil & Gas, Water Supply |

| Ball Valve | 120 | 24 | Medium | Chemical Processing, HVAC |

| Butterfly Valve | 80 | 18 | Medium | Water Treatment, HVAC |

| Check Valve | 95 | 36 | High | Pumping Stations, Marine |

| Pressure Relief Valve | 200 | 12 | Very High | Refinery, Chemical Plants |

Related Posts

-

Understanding the Different Types of Control Valves: A Comprehensive Guide

-

Discover Innovative Control Valve Types at the Upcoming Canton Fair in Guangzhou

-

Premium Quality Air Control Valves: Leading Global Exports from China

-

Understanding Industry Standards: How to Choose the Best Back Valve for Optimal Performance

-

Finding Top Suppliers for Best Valve Models with Industry Insights and Data

-

Unlocking the Advantages of Superior Air Control Valves for Enhanced Performance