Why Are Ball Bearings Important for Machines and Equipment?

Ball Bearings play a crucial role in the functioning of machines and equipment across various industries. According to a report by the Global Ball Bearing Market, the industry generated over $30 billion in revenue in 2021. This highlights the immense importance of ball bearings in ensuring the smooth operation of mechanical systems. These components reduce friction, enhance efficiency, and prolong the lifespan of machinery.

However, not all ball bearings are created equal. The choice of material and design can impact performance significantly. For instance, ceramic ball bearings offer lower friction but are more costly than steel types. Industry surveys suggest that almost 40% of machinery failures relate to bearing failures. This statistic underscores the need for proper selection and maintenance of ball bearings to avoid costly downtimes. The right ball bearing can make or break mechanical performance.

Recognizing the significance of ball bearings is essential for operational success. As industries continue to evolve, so too must our strategies in selecting and utilizing these vital components. With the increasing pace of technological advancement, revisiting traditional bearing choices can lead to improved performance and reliability in machines.

Importance of Ball Bearings in Mechanical Systems

Ball bearings play a crucial role in the functionality of mechanical systems. They reduce friction between moving parts, allowing machinery to operate smoothly. This friction reduction increases efficiency and prolongs the lifespan of equipment. When machines run with less resistance, they consume less energy. This can lead to noticeable cost savings over time.

In addition to efficiency, ball bearings maintain precise alignment. They support rotating components and distribute loads evenly. This alignment helps prevent wear on parts, which can lead to breakdowns. A small issue, such as improper maintenance or incorrect installation, can cause significant problems. Regular checks are essential to ensure everything is functioning as it should.

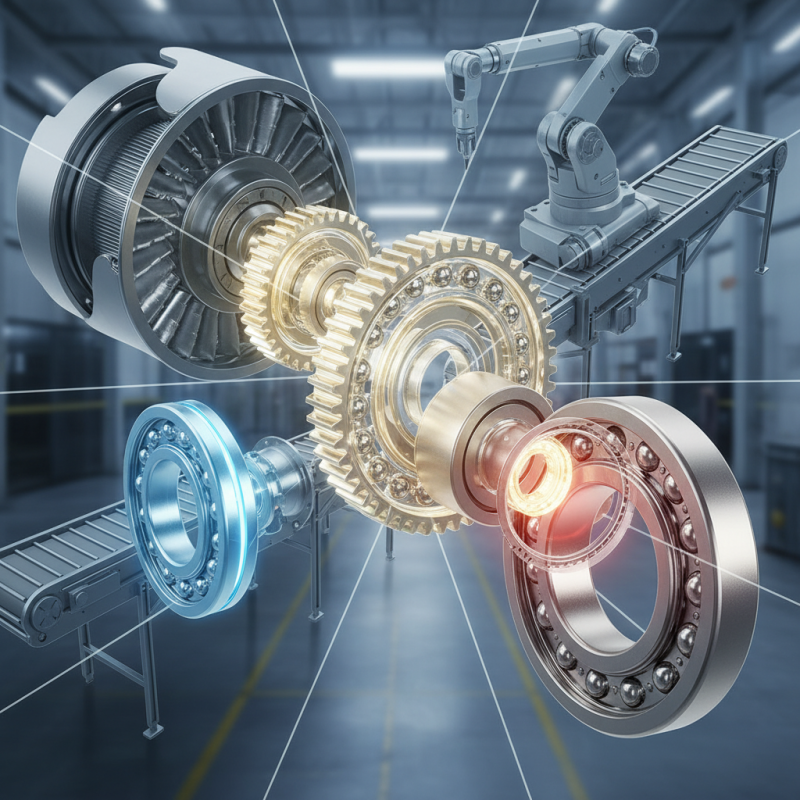

The versatility of ball bearings cannot be overlooked. They are used in various applications, from small electronics to large industrial machinery. However, choosing the right type of bearing for a specific application can be challenging. Each system has unique demands, making it critical to consider various factors. Sometimes, overlooking these details can lead to inefficiencies or failures that could have been easily avoided.

Why Are Ball Bearings Important for Machines and Equipment?

| Dimension | Importance | Applications |

|---|---|---|

| Load Distribution | Helps in evenly distributing the load across rotating parts, reducing wear. | Electric motors, machinery |

| Friction Reduction | Minimizes friction between moving surfaces, improving efficiency. | Automotive parts, conveyor systems |

| Precision and Accuracy | Ensures precise movement and functioning of components. | Robotics, CNC machines |

| Durability | Designed to withstand high stress and long operational life. | Industrial machinery, aerospace |

| Vibration Damping | Reduces vibrations created by rotating parts, enhancing stability. | HVAC systems, drilling equipment |

Functionality of Ball Bearings in Reducing Friction

Ball bearings play a vital role in machinery. They provide a crucial function: reducing friction. When two surfaces move against each other, friction creates heat. This heat can wear down components. Ball bearings minimize direct contact, allowing for smoother movement. Their design helps distribute weight evenly. This leads to less wear and tear on machinery.

In various applications, the effectiveness of ball bearings is clear. In electric motors, they enable high-speed rotation. In bicycles, they make pedaling effortless. Yet, not all ball bearings are created equal. Poor quality bearings can lead to breakdowns. This raises questions about manufacturing standards. Choosing the right bearing for specific tasks is essential. It affects overall performance and durability.

Maintaining ball bearings is also critical. Over time, they can accumulate dirt and grime. This can inhibit their ability to reduce friction effectively. Regular inspections and cleanings can make a big difference. Some may overlook this aspect, leading to premature failures. The importance of ball bearings simply cannot be diminished.

Types of Ball Bearings and Their Applications

Ball bearings are essential components found in various machines and equipment. They reduce friction between moving parts, enhancing efficiency. There are several types of ball bearings, each suited for different applications.

Deep groove ball bearings are among the most common. They handle radial and axial loads. These bearings allow machines to run smoothly at high speeds. According to a report by the International Society of Automation, they are widely used in electric motors and conveyor systems.

Another type is angular contact ball bearings. They are designed for combined loads. This makes them ideal for applications in aerospace and automotive industries. They can handle high-speed rotation while maintaining durability.

Tips: Regular maintenance can extend the life of your bearings. Monitor for unusual noises or vibrations. Replace bearings at the first sign of wear to avoid costly machinery breakdown.

Self-aligning ball bearings are also popular. They can accommodate misalignment, which is beneficial for heavy machinery. Their design allows for easy assembly and operation. However, they may require more space than other types.

Evaluating the right type of ball bearing is crucial. It affects performance and longevity. Make sure to account for load requirements and operating conditions to make an informed choice.

Factors Influencing Ball Bearing Performance

Ball bearings are critical components in machinery. Their performance can significantly affect operational efficiency. Various factors influence this performance. Understanding these can help avoid failures and enhance machine longevity.

One major factor is lubrication. Proper lubrication reduces friction. It also prevents overheating. According to the International Journal of Engineering, around 65% of bearing failures relate to lubrication issues. Inadequate lubrication leads to unnecessary wear and can compromise performance. It’s essential to choose the right type of lubricant based on the operating environment.

Material quality is another key factor. High-quality steel bearings are less prone to deformation. A study by the American Society of Mechanical Engineers indicates that using substandard materials can reduce the lifespan of ball bearings by up to 30%. Additionally, the precision of the manufacturing process matters. Tolerances must be very tight to ensure smooth operation. Any slight variation can lead to increased vibration and wear. These details are often overlooked but can have significant implications.

Maintenance Practices for Prolonging Ball Bearing Life

Ball bearings play a critical role in the efficiency of machines and equipment. Their functionality directly affects productivity and performance. Prolonging the life of ball bearings is crucial to minimize downtime and reduce costs associated with maintenance. Regular maintenance practices can significantly enhance their durability.

Lubrication is key to a ball bearing’s longevity. According to a recent industry report, nearly 40% of bearing failures are attributed to inadequate lubrication. Proper grease application prevents wear, reduces friction, and minimizes heat generation during operation. Over-lubrication can also lead to problems, creating excess pressure and forcing out grease. Ensure that the right type and amount of lubricant is used.

Another important factor is alignment. Misalignment can lead to premature wear and significant damage. A study indicated that misalignment can reduce bearing life by 50%. Regular inspections using precise measurement tools help to maintain alignment. Vibration analysis can detect early signs of misalignment, allowing for timely intervention. These practices can make a considerable difference in the lifespan of ball bearings.