Essential Guide to Selecting Top Manufacturers: Solutions for Best At Control Valves Procurement

In the complex world of industrial procurement, selecting the right manufacturers for At Control Valves is critical to ensuring operational efficiency and reliability. With an array of options available, it can be daunting for procurement professionals to navigate through various suppliers, each offering different levels of quality, technology, and service. This essential guide aims to provide a comprehensive overview of the key criteria to consider when sourcing At Control Valves, from understanding industry standards to assessing supplier reliability and quality assurance processes.

By following these guidelines, you can make informed decisions that not only enhance the performance of your systems but also drive cost efficiency and mitigate risks associated with poor procurement choices. Join us as we delve into the solutions for optimizing your procurement strategy and fostering long-term partnerships with top manufacturers in the industry.

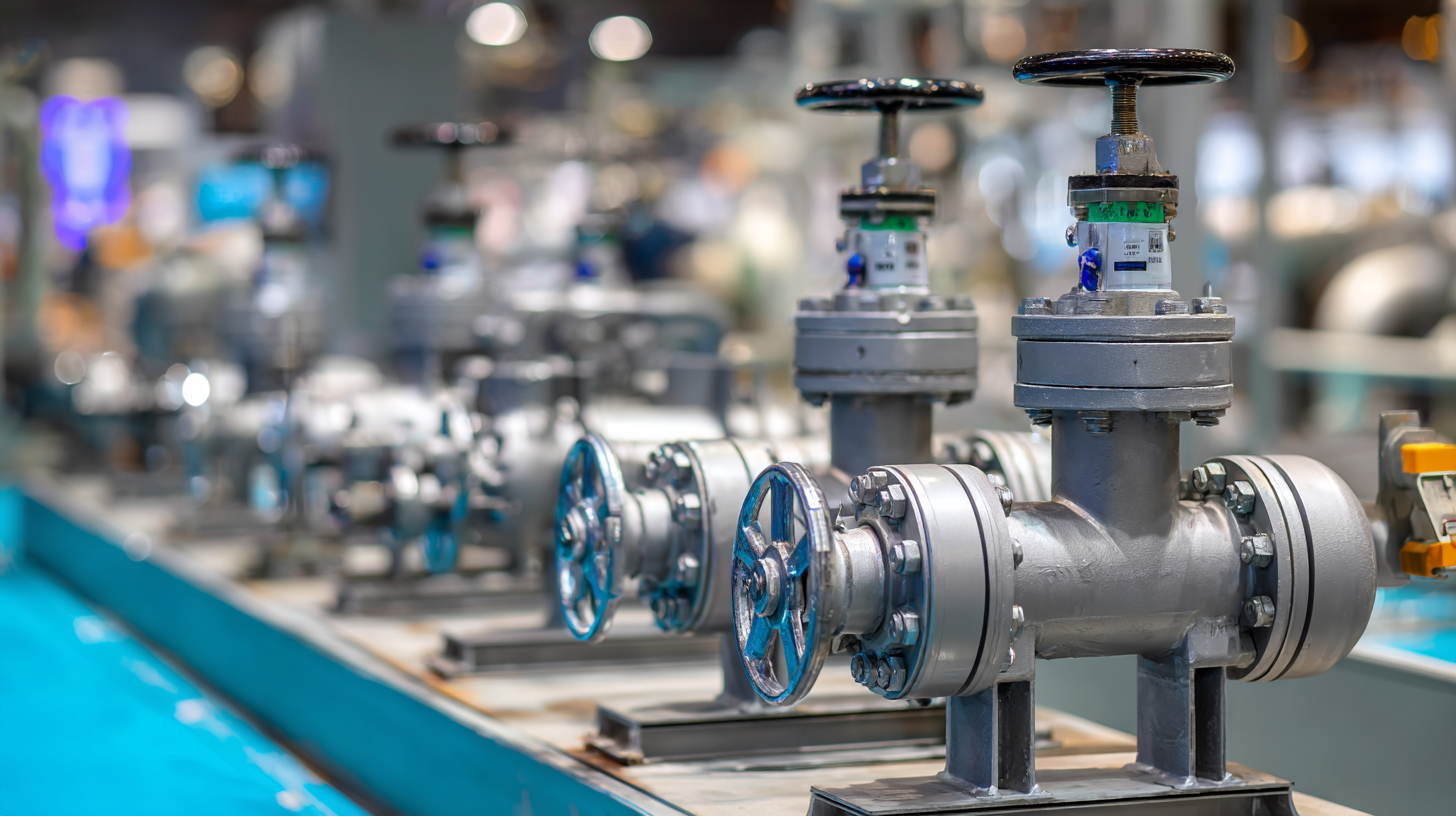

Understanding the Different Types of Control Valves and Their Applications

Control valves play a pivotal role in numerous industries, regulating flow and pressure to ensure efficient operations. A recent report by MarketsandMarkets indicates that the global control valves market is projected to reach USD 8.08 billion by 2025, growing at a CAGR of 5.6%. This growth underscores the increasing demand for various types of control valves tailored to specific applications. Key categories include globe valves, ball valves, butterfly valves, and diaphragm valves, each prized for unique characteristics suited to different operational conditions.

Globe valves are renowned for their excellent throttling capabilities, making them ideal for applications requiring precise flow control, such as in the chemical processing and oil & gas industries. Conversely, ball valves offer rapid on/off capabilities and minimal pressure drop, which are crucial in water supply and HVAC systems. Additionally, butterfly valves are often favored for their lightweight design and space-saving advantages, commonly employed in large volume applications like power generation and wastewater treatment. Understanding these distinctions not only helps in selecting the right control valve but also enhances procurement strategies to align with industry demands effectively.

Essential Guide to Selecting Top Manufacturers: Solutions for Best At Control Valves Procurement - Understanding the Different Types of Control Valves and Their Applications

| Control Valve Type | Application | Common Materials | Operating Pressure Range | Typical Features |

|---|---|---|---|---|

| Globe Valve | Flow Regulation | Cast Iron, Stainless Steel | Up to 600 psi | High Flow Control, Throttling |

| Ball Valve | On/Off Control | Brass, Stainless Steel | Up to 1500 psi | Quick Operation, Low Pressure Drop |

| Butterfly Valve | Flow Regulation | Plastic, Cast Iron, Stainless Steel | Up to 150 psi | Lightweight, Compact Design |

| Check Valve | Prevent Backflow | Brass, Stainless Steel | Up to 300 psi | Automatic Operation, Minimal Maintenance |

| Pressure Relief Valve | Pressure Regulation | Steel, Alloy, Composite | Up to 2500 psi | Safety Features, Adjustable Settings |

Key Factors to Consider When Sourcing Control Valve Manufacturers

When sourcing control valve manufacturers, various key factors must be taken into account to ensure optimal procurement. First and foremost, understanding the manufacturer’s experience and expertise in the control valve industry is crucial. Assessing their track record, industry certifications, and client testimonials can provide valuable insights into their reliability and the quality of their products. Manufacturers with extensive experience are often better equipped to handle complex specifications and provide tailored solutions to meet unique project requirements.

Another vital consideration is the manufacturer's commitment to quality assurance and compliance with industry standards. Evaluating their quality control processes will give you confidence in the durability and performance of the control valves. Look for manufacturers who employ rigorous testing protocols and adhere to recognized international standards, such as ISO certifications. Additionally, it's essential to consider their technological capabilities, including the use of advanced materials and innovative designs, which can enhance the efficiency and lifespan of the valves. By focusing on these key factors, you can make informed decisions and foster successful partnerships with top control valve manufacturers.

Control Valve Manufacturers Procurement Analysis

Market Trends: The Growing Demand for Smart Control Valves

The market for control valves is undergoing a significant transformation, driven by the growing demand for smarter and more efficient solutions in various industries. Smart control valves are increasingly being recognized for their ability to enhance operational efficiency, reduce waste, and optimize process control. This trend is particularly prominent in sectors such as oil and gas, water treatment, and manufacturing, where precise flow control is critical for performance and safety.

As companies embrace Industry 4.0 principles, the integration of automation and data analytics into control valve systems has become essential. Smart control valves, equipped with advanced sensors and connectivity features, enable real-time monitoring and predictive maintenance, significantly reducing downtime and operational costs. This technological evolution is not only meeting the existing demand but is also paving the way for innovative applications across diverse sectors, further driving the market growth.

Manufacturers are responding to this trend by investing in R&D to develop intelligent valve systems that offer greater flexibility and adaptability. As the competition intensifies, it is crucial for procurement managers to select suppliers who are not only leaders in technology but also committed to sustainability and quality assurance. This strategic approach will ensure that organizations remain competitive in a rapidly evolving market landscape.

Evaluating Manufacturer Certifications and Quality Standards in Control Valves

When selecting manufacturers for control valves, assessing their certifications and quality standards is crucial. Certifications such as ISO 9001 demonstrate a manufacturer’s commitment to maintaining high-quality management systems. This standard not only assures the consistency of products but also highlights a company’s ability to meet customer requirements and regulatory demands. Additionally, specific certifications for valves, such as API 6D or CE marking, indicate compliance with industry standards, ensuring that the products meet safety and performance expectations.

Quality standards extend beyond certifications; they encompass a manufacturer’s adherence to rigorous testing and inspection procedures throughout the production process. It’s essential to evaluate a manufacturer's quality control protocols, including routine audits and performance evaluations. Manufacturers that implement advanced quality assurance processes can better mitigate risks associated with valve failures in critical applications. Furthermore, engaging with past customers for feedback on the manufacturer's quality and reliability can provide valuable insights into their operational integrity and long-term performance. Prioritizing these factors will help ensure that your procurement of control valves aligns with the highest performance and reliability standards.

Cost Analysis: Balancing Quality and Affordability in Control Valve Procurement

When procuring control valves, a critical aspect that often challenges decision-makers is the balance between cost and quality. Striking this balance is essential, as the functionality and reliability of control valves directly impact your operations. High-quality valves may come with a higher price tag, but they often provide superior performance and longevity, which can lead to significant cost savings in maintenance and replacements over time. Therefore, it's vital to conduct a thorough cost analysis that goes beyond initial purchase price to consider the total cost of ownership.

Another pivotal element in the cost analysis process is understanding the specific requirements of your application. This includes evaluating the operational environment, pressure specifications, and fluid characteristics, which can dictate the type of valves needed. Engaging with manufacturers early in the procurement process allows for insights into product specifications and potential cost-saving alternatives that do not compromise quality. By comparing various manufacturers and their offerings, you can identify those that not only meet your budgetary constraints but also provide reliable and efficient solutions suited to your operational needs. The objective is to make informed decisions that harmonize cost-effectiveness with the durability and performance necessary for optimal operation.