10 Essential Features of Pressure Valves You Should Know

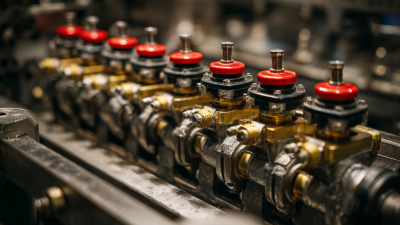

Pressure valves are critical components in various industries, ensuring safe and efficient operation of systems that handle fluids and gases under pressure. According to a recent report by MarketsandMarkets, the global market for pressure valves is projected to reach USD 40.5 billion by 2026, growing at a CAGR of 5.2% from 2021. This growth is driven by increasing demand in sectors such as oil and gas, water and wastewater treatment, and power generation. As industries become more focused on enhancing safety protocols and optimizing performance, understanding the essential features of pressure valves becomes paramount. In this blog, we will delve into 10 crucial characteristics of pressure valves that every engineer and technician should know to ensure proper selection, installation, and maintenance, ultimately contributing to operational integrity and safety across various applications.

Characteristics of Pressure Relief Valves: An Overview of Alternatives

Pressure relief valves (PRVs) are critical components in various industrial and commercial applications, ensuring safety and maintaining system integrity. These valves work by automatically venting excess pressure from a system, preventing potential hazards such as explosions or equipment failure. However, understanding the characteristics of different types of pressure relief valves is essential for selecting the right one for your specific needs.

When exploring alternatives to traditional PRVs, it's important to consider options like safety valves, which offer quick response times and reliable operation, or relief/dump valves, which are ideal for larger flow applications. Each type possesses unique features tailored for various operating conditions. Additionally, the materials used in construction, such as stainless steel or high-temperature alloys, can significantly impact durability and performance. Thus, comprehending these characteristics will enable better decision-making when it comes to system design and maintenance.

10 Essential Features of Pressure Valves You Should Know

| Feature | Description | Advantages | Common Applications |

|---|---|---|---|

| Type of Valve | Defines the design and functionality of the valve. | Tailored for specific pressure control. | Oil & gas, chemical processing. |

| Set Pressure | The pressure level at which the valve begins to open. | Ensures system safety by preventing overpressure. | Industrial boiler systems. |

| Material Compatibility | Ability to withstand fluid characteristics without degradation. | Enhances valve lifespan and lowers maintenance costs. | Water treatment, chemical manufacturing. |

| Response Time | The speed at which the valve reacts to pressure changes. | Immediate intervention helps in preventing accidents. | Critical systems like nuclear reactions. |

| Flow Capacity | Amount of fluid that can pass through the valve. | Prevents bottlenecks in high-demand situations. | Heavy machinery, fuel transportation. |

| Temperature Range | Operational temperature limits of the valve. | Ensures functionality in extreme environments. | Power plants, petrochemical plants. |

| Actuation Type | Mechanism that opens and closes the valve. | Can be manual, pneumatic, or electric for flexibility. | Automated systems and remote operations. |

| Maintenance Needs | Frequency and type of service required for upkeep. | Minimize downtime through efficient scheduling. | Water treatment facilities, HVAC systems. |

| Design Standards | Regulatory requirements the valve must meet. | Enhances trust and compliance in critical applications. | Medical applications, aerospace systems. |

How to Choose Between Spring-Loaded and Pilot-Operated Valves

When it comes to choosing between spring-loaded and pilot-operated pressure valves, understanding their distinctive features is crucial for optimal performance in various applications. Spring-loaded valves are typically simpler in design and operation. They use a spring mechanism to maintain a specific pressure within the system, making them suitable for applications that demand immediate response to pressure fluctuations. According to industry reports, spring-loaded valves are favored in situations where quick actuation is necessary, contributing to about 60% of the market share in smaller, low-pressure applications.

On the other hand, pilot-operated valves offer enhanced control and are ideal for high-pressure systems. They rely on a small pilot valve to control the larger main valve, providing greater precision and stability in maintaining desired pressure levels. Recent market analyses have shown that pilot-operated valves are gaining popularity in industrial processes, accounting for an estimated 40% of the market as industries look for solutions that offer reliability and reduced maintenance costs. With advancements in digital technology, manufacturers are able to optimize these valves, resulting in increased capacity and reduced procurement costs—projected to enhance annual revenues by nearly ten million by 2024 in sectors like hydraulic systems and fluid control.

Exploring Electrically Actuated Pressure Valves: Benefits and Applications

Electrically actuated pressure valves are at the forefront of modern fluid control technologies, combining precision with automation to optimize operational efficiency. These valves utilize electric power to open or close, allowing for swift and accurate adjustments in pressure within systems. This capability is particularly beneficial in industries such as manufacturing and petrochemicals, where maintaining specific pressure levels is crucial for safety and performance. By minimizing the need for manual intervention, electrically actuated valves not only enhance productivity but also reduce the likelihood of human error.

Electrically actuated pressure valves are at the forefront of modern fluid control technologies, combining precision with automation to optimize operational efficiency. These valves utilize electric power to open or close, allowing for swift and accurate adjustments in pressure within systems. This capability is particularly beneficial in industries such as manufacturing and petrochemicals, where maintaining specific pressure levels is crucial for safety and performance. By minimizing the need for manual intervention, electrically actuated valves not only enhance productivity but also reduce the likelihood of human error.

The applications of electrically actuated pressure valves are broad and varied, spanning from environmental control systems in HVAC to intricate chemical processing plants. Their ability to respond rapidly to fluctuations in pressure ensures that equipment operates within safe limits, preventing potential failures or hazardous incidents. Furthermore, the integration with automation systems allows for real-time monitoring and control, enabling operators to optimize processes and maintain consistent product quality. As industries continue to adopt smart technologies, the role of these valves will be vital in driving innovation and efficiency.

Comparative Analysis of Conventional vs. Smart Pressure Control Systems

When it comes to pressure control systems, a comparative analysis of conventional versus smart systems reveals significant distinctions in functionality and efficiency. Conventional pressure valves typically rely on mechanical mechanisms that control pressure based on fixed settings. These systems may limit flexibility, resulting in inefficiencies and higher operational costs. They also often require manual intervention for adjustments, which can lead to delays in response time during pressure fluctuations and potential safety hazards.

On the other hand, smart pressure control systems leverage advanced technology, including sensors and software algorithms, to optimize performance dynamically. These systems provide real-time data analysis, allowing for immediate adjustments to pressure settings based on current operational conditions. Smart pressure valves contribute to improved energy efficiency and enhanced safety by anticipating changes rather than reacting after the fact. As industries increasingly prioritize automation and efficiency, the transition toward smart systems represents a significant leap forward in pressure management technology.

10 Essential Features of Pressure Valves: Comparative Analysis of Conventional vs. Smart Pressure Control Systems

Understanding the Role of Materials in Valve Performance and Longevity

When considering the performance and longevity of pressure valves, the materials used in their construction play a critical role. Valves made from high-grade stainless steel offer superior resistance to corrosion and wear, significantly extending their lifespan. According to a report by the American Society of Mechanical Engineers (ASME), choosing the right materials can improve valve durability by up to 30%, ensuring that they function effectively even under extreme pressure conditions.

Tips: Select materials based on the specific environment where the valve will be used. For example, if your application involves high temperatures, consider ceramic or alloy materials that can withstand thermal expansion while maintaining structural integrity.

Moreover, the manufacturing processes also influence material performance. Techniques such as forging and machining can create smoother surfaces which reduce friction and enhance sealing capabilities. According to a recent market analysis, valves incorporating advanced manufacturing technology can reduce leak rates by over 50%, highlighting the importance of not only the materials but also how they are processed.

Tips: Regular maintenance and inspections can identify wear early on, ensuring that material degradation does not lead to catastrophic failures in applications involving critical flow control.

Related Posts

-

Understanding Import Export Certifications for Best Pressure Valves with a Step by Step Guide

-

Premium Quality Air Control Valves: Leading Global Exports from China

-

Crafted in China's Leading Factory: The Trusted Excellence of Best Hydraulic Control Worldwide

-

Unlocking the Advantages of Superior Air Control Valves for Enhanced Performance

-

Finding Top Suppliers for Best Valve Models with Industry Insights and Data

-

Understanding the Different Types of Control Valves: A Comprehensive Guide