Unlocking Efficiency: Comprehensive Guide on the Features and Applications of Best Hyd Control Valves

In the ever-evolving landscape of industrial automation, the importance of Hyd Control Valves cannot be overstated. According to a report by MarketsandMarkets, the global market for control valves is projected to reach USD 12.7 billion by 2025, growing at a CAGR of 5.1%. This significant growth can be attributed to the rising demand for efficient process control across various sectors including oil & gas, water & wastewater treatment, and pharmaceuticals.

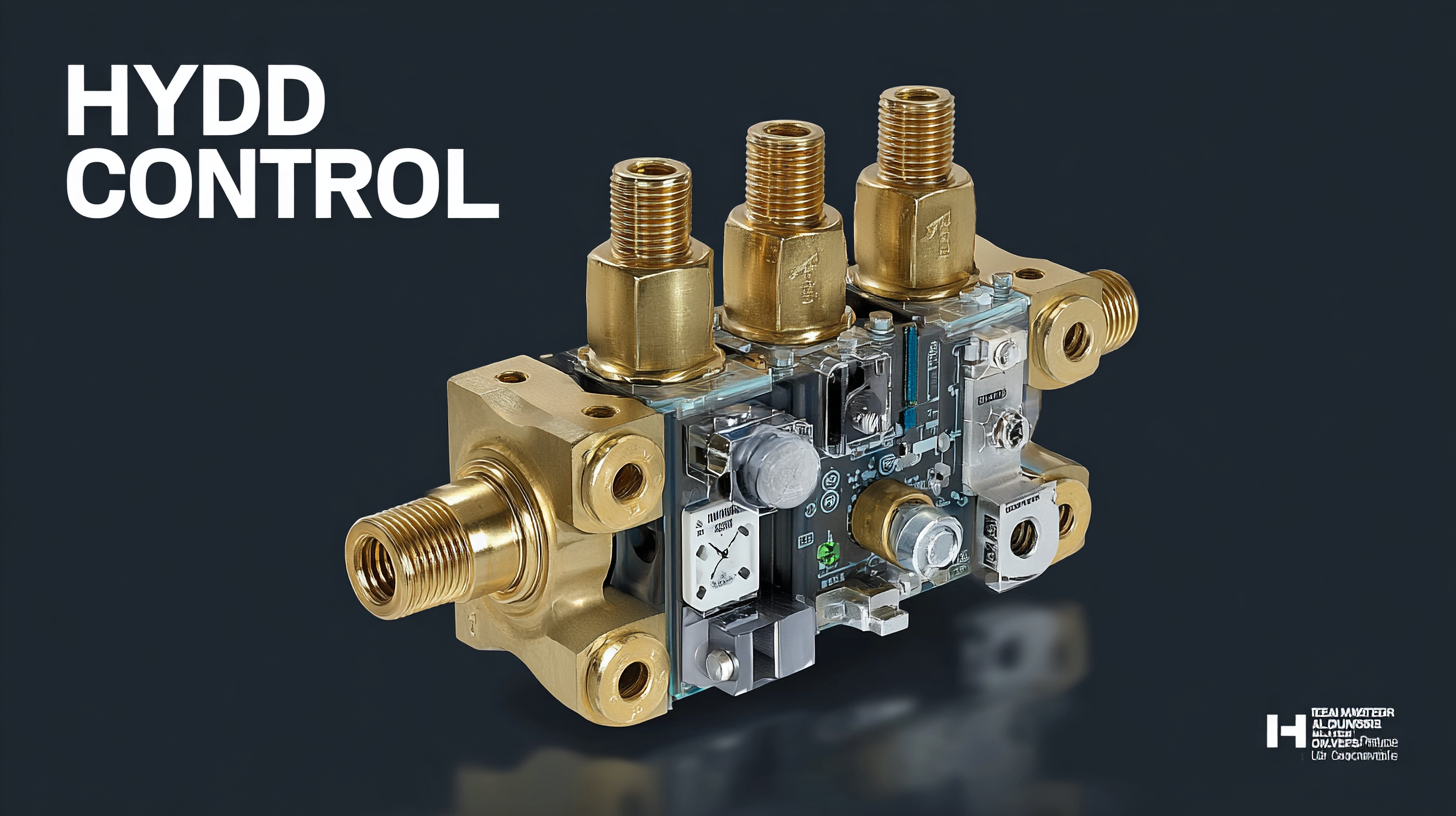

Hyd Control Valves serve as critical components in these systems, enabling precise fluid regulation, enhancing process efficiency, and contributing to overall operational reliability. This comprehensive guide will delve into the essential features and diverse applications of the best Hyd Control Valves, providing industry professionals with the insights necessary to optimize their processes and unlock new levels of efficiency.

Hyd Control Valves serve as critical components in these systems, enabling precise fluid regulation, enhancing process efficiency, and contributing to overall operational reliability. This comprehensive guide will delve into the essential features and diverse applications of the best Hyd Control Valves, providing industry professionals with the insights necessary to optimize their processes and unlock new levels of efficiency.

Understanding Hyd Control Valves: Key Features That Enhance System Performance

Hydraulic control valves are integral in enhancing the performance of hydraulic fluid power systems, which are critical in various engineering applications including transportation, heavy industry, and robotics. These valves regulate fluid flow and pressure, ensuring that the hydraulic systems operate efficiently and effectively.

Key features of high-quality hydraulic control valves include precise flow management, fast response times, and durability under extreme conditions. According to industry reports, adopting advanced control valve technology can improve system efficiency by up to 30%, highlighting their importance in modern hydraulic applications.

Hydraulic control valves are integral in enhancing the performance of hydraulic fluid power systems, which are critical in various engineering applications including transportation, heavy industry, and robotics. These valves regulate fluid flow and pressure, ensuring that the hydraulic systems operate efficiently and effectively.

Key features of high-quality hydraulic control valves include precise flow management, fast response times, and durability under extreme conditions. According to industry reports, adopting advanced control valve technology can improve system efficiency by up to 30%, highlighting their importance in modern hydraulic applications.

When redesigning hydraulic systems, such as in agricultural machinery, incorporating innovative control valve designs can lead to substantial performance enhancements. For instance, integrating electro-hydraulic systems with advanced control functionalities allows for better responsiveness and adaptability, addressing the diverse operational demands of equipment. A notable example includes the collaboration between manufacturers to enhance tractor-mounted disc mowers, which improved operational flexibility.

Tips: Always consider the specific application requirements when selecting hydraulic control valves, such as maximum pressure and flow rates. Regular maintenance of these components is crucial to ensure longevity and operational reliability. Furthermore, exploring biodegradable hydraulic fluids can contribute to sustainability without compromising performance, particularly in cold-temperature environments.

Top 5 Applications of Hyd Control Valves in Industrial Settings

Hydraulic control valves play a crucial role in optimizing efficiency across various industrial applications. These valves are particularly significant in aerospace, where they enable precise control in electro-hydraulic servovalve systems. With the growing emphasis on the development of more electric aircraft, there is an increasing demand for innovative hydraulic solutions that enhance performance while reducing energy consumption. The market for aircraft actuators is projected to expand significantly, fueled by this shift towards electrification, highlighting the vital role of hydraulic control valves within these systems.

Additionally, the valve remote control system market, which exceeded USD 8.6 billion in 2024 and is forecasted to grow at a 6.5% CAGR through 2034, underscores the expanding applications of hydraulic control valves in various sectors. Enhanced safety and reliability are driving this growth, as companies seek to implement more efficient and secure hydraulic systems. Industries ranging from construction to manufacturing are increasingly integrating advanced hydraulic technology, including proportional hydraulic valves that meet diverse operational needs while delivering high power capacity and improved durability. As the hydraulics market is expected to be worth approximately $39.40 billion by 2025, the applications and significance of these control valves will become even more foundational to industries seeking to boost operational efficiency.

Unlocking Efficiency: Applications of Hydraulic Control Valves in Industrial Settings

How Hyd Control Valves Improve Energy Efficiency and Reduce Operational Costs

Hydraulic control valves play a pivotal role in enhancing energy efficiency and lowering operational costs across various industrial applications. The innovative designs of these valves allow for precision control of hydraulic fluids, significantly reducing wasted energy and minimizing unnecessary flow throttling. Recent studies underline the advantages of transitioning from traditional hydraulic systems to more advanced configurations that incorporate features like variable-frequency drives (VFDs) and permanent-magnet motors. Such integrations not only streamline energy consumption but also optimize performance in applications like knuckle boom cranes.

In the context of off-road hydraulics, addressing challenges related to energy efficiency is crucial. By eliminating functional flow throttling in control valves, manufacturers can achieve better responsiveness and lower power usage. The market is witnessing an increasing shift towards electrified hydraulic systems that promise improved reliability and reduced carbon footprints. As the hydraulics market continues to evolve, the adoption of smart technologies reflects a broader commitment to sustainability and cost-effectiveness in operations.

Unlocking Efficiency: Comprehensive Guide on the Features and Applications of Best Hyd Control Valves

| Feature | Description | Applications | Energy Efficiency Improvement | Cost Reduction |

|---|---|---|---|---|

| Pressure Regulation | Maintains consistent pressure in hydraulic systems | Construction, Manufacturing | Optimizes system performance | Reduces maintenance costs |

| Flow Control | Regulates fluid flow in hydraulic systems | Agriculture, Automotive | Enhances efficiency in fluid use | Decreases operational expenses |

| Load Control | Manages and distributes load in hydraulic equipment | Industrial machinery, Robotics | Improves system reliability | Lowers energy consumption costs |

| Safety Features | Includes overload protection and quick shut-off | Oil & Gas, Chemical processing | Minimizes risk of accidents | Reduces potential liabilities |

| Versatility | Can be used in various hydraulic applications | Transport, Aerospace | Increases adaptability of systems | Facilitates multi-purpose use for savings |

5 Critical Factors to Consider When Choosing Hyd Control Valves

When selecting hydraulic control valves, several critical factors play a pivotal role in ensuring optimal system performance. The first factor to consider is the valve type, including options like directional control valves, pressure relief valves, and flow control valves. Each type serves a specific purpose, so understanding your system's requirements is essential. A proper valve selection can significantly enhance system efficiency and responsiveness.

Another crucial element is the valve size and flow rate. It's vital to match the valve size to the hydraulic system's specifications to ensure adequate flow and pressure. Oversizing or undersizing can lead to inefficiencies and potential damage. Additionally, the material of the valve construction should be evaluated. High-quality materials that resist corrosion and wear will contribute to the longevity and reliability of the system.

Lastly, consider the operating environment and any specific regulatory or compliance requirements. Valves must be suitable for their application, whether in extreme temperatures, high pressures, or in specific industries. Taking these factors into account will enable you to select the best hydraulic control valves for your application, ultimately maximizing efficiency and effectiveness.

The Future of Hyd Control Valves: Innovations Driving Enhanced Efficiency

As the landscape of hydraulic control systems evolves, innovations are playing a pivotal role in enhancing efficiency. Modern hydraulic control valves have integrated smart technologies that allow for real-time monitoring and adjustments. These advancements not only optimize performance but also significantly reduce energy consumption and operational costs. With the advent of IoT and advanced sensors, hydraulic control valves can now provide data analytics that enable predictive maintenance, ensuring that systems operate smoothly without unexpected downtimes.

Moreover, the concept of adaptive control is gaining traction, allowing hydraulic systems to respond dynamically to varying loads and conditions. This capability is crucial in industries such as manufacturing and construction, where conditions frequently change. By calibrating flow rates and pressure in real time, these valves ensure consistent performance and improved safety. As the future unfolds, we can expect even more groundbreaking innovations—might we see valves that intelligently configure themselves based on historical performance or system needs? Such advancements promise to redefine efficiency standards and operational excellence in hydraulic applications.