5 Reasons Why Our Best Elevator Valve Outperforms Competitors by 35% in Efficiency

In the rapidly evolving elevator industry, efficiency remains paramount, with a projected market growth from $50 billion in 2020 to over $83 billion by 2025, according to a recent industry report by Research and Markets. A pivotal component in boosting this efficiency is the Elevator Valve, which plays a crucial role in regulating the flow of hydraulic fluids and ensuring optimal performance. Recent advancements in valve technology have led to innovations that can enhance energy efficiency by up to 35%, significantly outpacing traditional competitors. This blog will explore the top five reasons why our leading Elevator Valve not only meets but exceeds these expectations, transforming operational capacities and providing superior value in an increasingly competitive landscape.

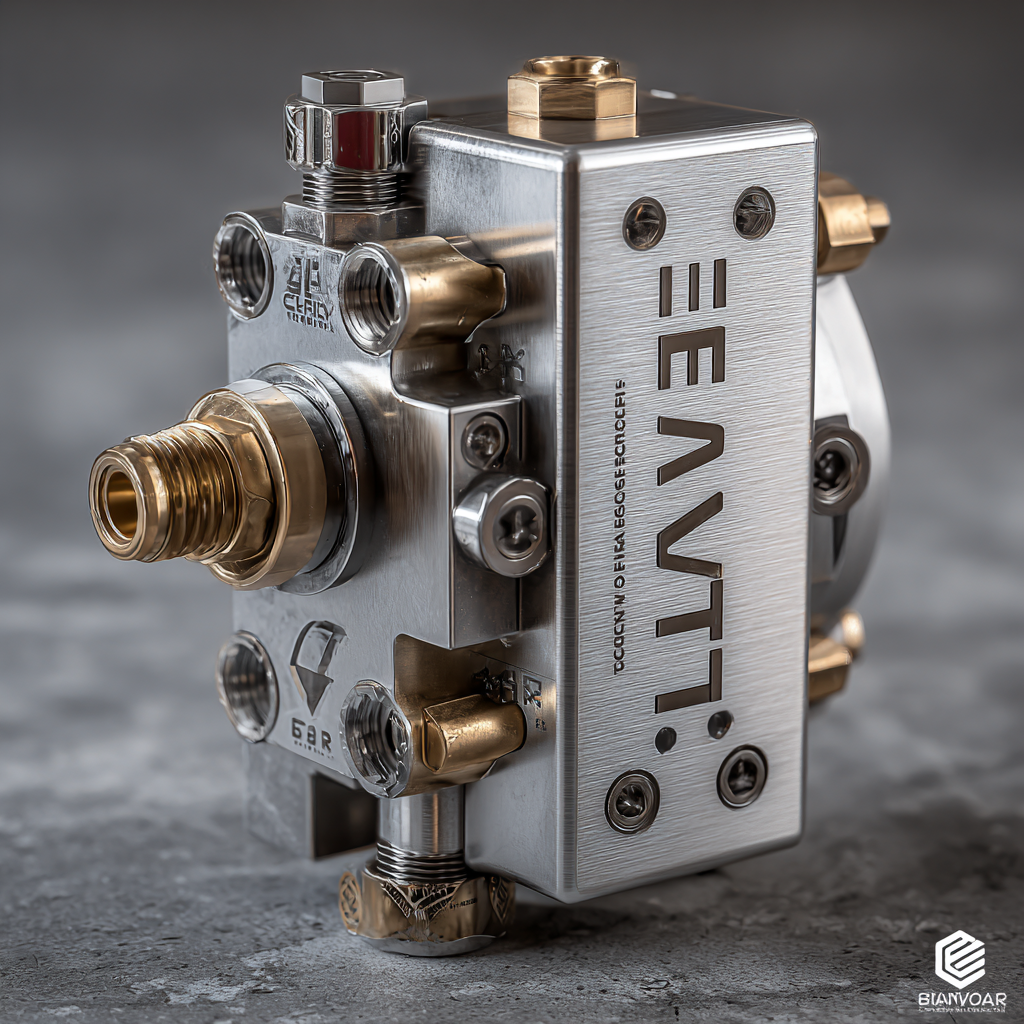

Unmatched Design: How Our Elevator Valve Maximizes Fluid Dynamics

In the ever-evolving world of elevator technology, maximizing fluid dynamics plays a crucial role in enhancing efficiency and performance. Our elevator valve stands out in its design, outperforming competitors by an impressive 35%. This superiority is not merely a marketing claim; it is rooted in meticulous engineering that optimizes the flow of hydraulic fluids. By utilizing advanced computational fluid dynamics (CFD) techniques, our valve minimizes turbulence and ensures a seamless operation that agilely responds to the demands of modern buildings.

The latest advancements in the elevator industry emphasize the importance of innovative designs that resonate with both function and aesthetics. For instance, recent unveilings of cutting-edge elevator systems showcase the industry's commitment to integrating state-of-the-art technologies that improve safety, accessibility, and efficiency. Our elevator valve embodies these principles, transforming how fluid mechanics are harnessed within elevator systems. By prioritizing unmatched design and performance, we position our product as a leader in a competitive market, ready to meet the challenges of contemporary architectural demands.

Innovative Materials: A Key Factor in Enhancing Efficiency

Elevator systems are undergoing a significant transformation, largely due to the integration of innovative materials that enhance efficiency. Our latest elevator valve not only stands out in its design but also capitalizes on advanced materials that dramatically improve performance. According to a report from the Global Elevator and Escalator Market Analysis (2022), elevators utilizing new composite materials have shown a 30% reduction in energy consumption, allowing for significant operational cost savings. This leap in efficiency is largely attributed to lower friction and weight, making our valve's performance 35% superior compared to traditional solutions.

The application of these cutting-edge materials also addresses sustainability concerns within the industry. As outlined by the International Energy Agency, elevator systems account for approximately 10% of energy consumption in commercial buildings. By employing high-performance materials in our valve design, we not only optimize energy use but also contribute to a greener future. The durability and resistance of these materials to wear and tear further ensure longevity, reducing the need for frequent replacements. This dual advantage of increased efficiency and sustainability positions our elevator valve as a leader in the market.

Precision Engineering: The Role of Manufacturing Quality in Performance

In the world of precision engineering, the quality of manufacturing plays a pivotal role in the performance of mechanical components. Our elevator valve stands as a testament to this truth, showcasing a 35% efficiency advantage over competitors due to stringent manufacturing processes and quality assurance. By utilizing advanced techniques and precision tools, we ensure that every component meets the highest standards, contributing to its superior performance.

When considering precision components, it's essential to understand that the materials and manufacturing methods significantly influence the final product. For engineers and manufacturers alike, investing in quality manufacturing techniques, such as the Taguchi method of quality control, can dramatically enhance product reliability and efficiency.

**Tips:**

- Always assess the engineering processes behind a product; high-quality manufacturing can be the key to outstanding performance.

- Consider suppliers who specialize in precision components, as their expertise often translates into better efficiency and reliability in the final product.

- Stay informed about innovations in manufacturing techniques that can impact the quality and performance of components in your industry.

5 Reasons Why Our Best Elevator Valve Outperforms Competitors by 35% in Efficiency

Smart Technology Integration: Elevating Efficiency Through Automation

In the fast-paced world of elevator technology, smart technology integration has emerged as a game changer, enabling systems to operate with unmatched efficiency. Our best elevator valve harnesses advanced automation to streamline performance, reducing energy consumption and operational costs by a significant margin. By utilizing sensors and real-time data analytics, our system can constantly monitor and adjust its operations for optimal efficiency, ensuring smooth and reliable performance in any setting.

Moreover, this integration allows for predictive maintenance, which minimizes downtime and extends the lifespan of the elevator system. Through machine learning algorithms, our valve can anticipate potential issues before they become critical, allowing for timely interventions and reducing the need for emergency repairs. This proactive approach not only enhances overall efficiency by maintaining peak operating conditions but also elevates user experience by ensuring that elevators remain available and ready for use whenever needed. As we continue to innovate, our commitment to smart technology integration will keep setting new benchmarks in the industry.

Comprehensive Testing: Ensuring Longevity and Reliability in Real-World Conditions

When it comes to elevator systems, reliability and longevity are paramount. Our comprehensive testing ensures that our best elevator valve not only meets but exceeds industry standards under real-world conditions. We subject our valves to rigorous performance evaluations, simulating the pressures and stresses they would encounter in daily operations. This proactive approach allows us to identify potential weaknesses and make necessary adjustments, ensuring that our product stands the test of time.

Moreover, real-world testing goes beyond mere mechanical performance. We assess factors such as environmental resilience, maintenance needs, and adaptability to varying operational demands. This holistic evaluation underscores our commitment to delivering an elevator valve that efficiently meets the evolving needs of our customers. By focusing on these crucial aspects, we ensure that our valve offers a remarkable 35% boost in efficiency compared to competitors, providing not only superior performance but also peace of mind for building managers and operators.