Understanding the Future of Control Hydraulic Systems in Modern Engineering

The evolution of Control Hydraulic systems has become paramount in modern engineering, reflecting advancements in automation and precision. Recent industry reports estimate that the global hydraulic systems market will reach USD 59.25 billion by 2026, growing at a CAGR of 5.6% from 2021, driven by increasing demand for efficient power transmission across various sectors such as manufacturing, construction, and aerospace. As the complexity of engineering applications escalates, the integration of sophisticated control hydraulic technologies is essential for enhancing operational efficiency and safety.

The implementation of digital solutions and smart sensors in hydraulic control systems is expected to optimize performance and reduce downtime, aligning with the growing trend towards Industry 4.0. These developments not only improve the reliability of hydraulic systems but also offer significant energy savings, with studies indicating that modern control hydraulic systems can achieve up to 30% greater efficiency compared to traditional setups. Understanding these dynamics is crucial for engineers and industry stakeholders aiming to leverage this transformative technology for future applications.

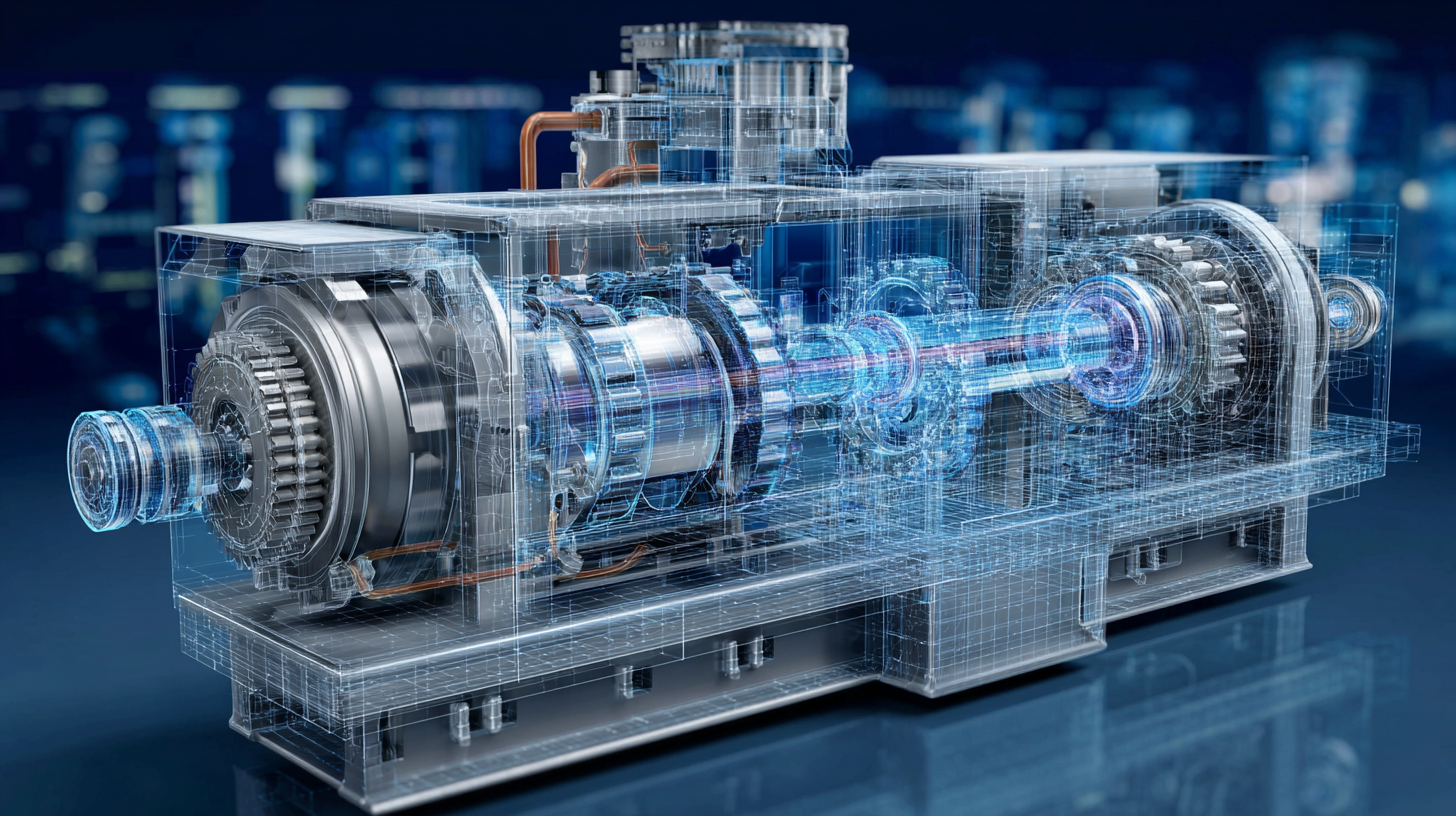

The Rise of Digital Twins in Hydraulic Systems for Predictive Maintenance

The integration of digital twins in hydraulic systems is revolutionizing predictive maintenance by enabling real-time monitoring and data analysis. This technology allows engineers to create virtual replicas of hydraulic components, providing insights into their operation and behavior under different conditions. By leveraging AI and machine learning, these digital twins can predict failures before they occur, significantly reducing unplanned outages that can cost companies substantial amounts in lost revenue. In sectors such as oil and gas or aerospace, where every hour of downtime can lead to significant financial losses, the implementation of digital twin technology represents a transformative leap forward in operational efficiency.

Moreover, the application of digital twins extends beyond mere failure prediction; it enhances overall system resilience. For example, in innovative frameworks developed for hydropower operations, digital twins paired with deep learning techniques can optimize performance and improve fault detection. This holistic approach to system management not only addresses immediate maintenance needs but also offers a pathway to sustainable engineering practices. As the industry embraces these advancements, the future of hydraulic systems management looks increasingly data-driven and proactive, promising to enhance reliability and safety across various engineering domains.

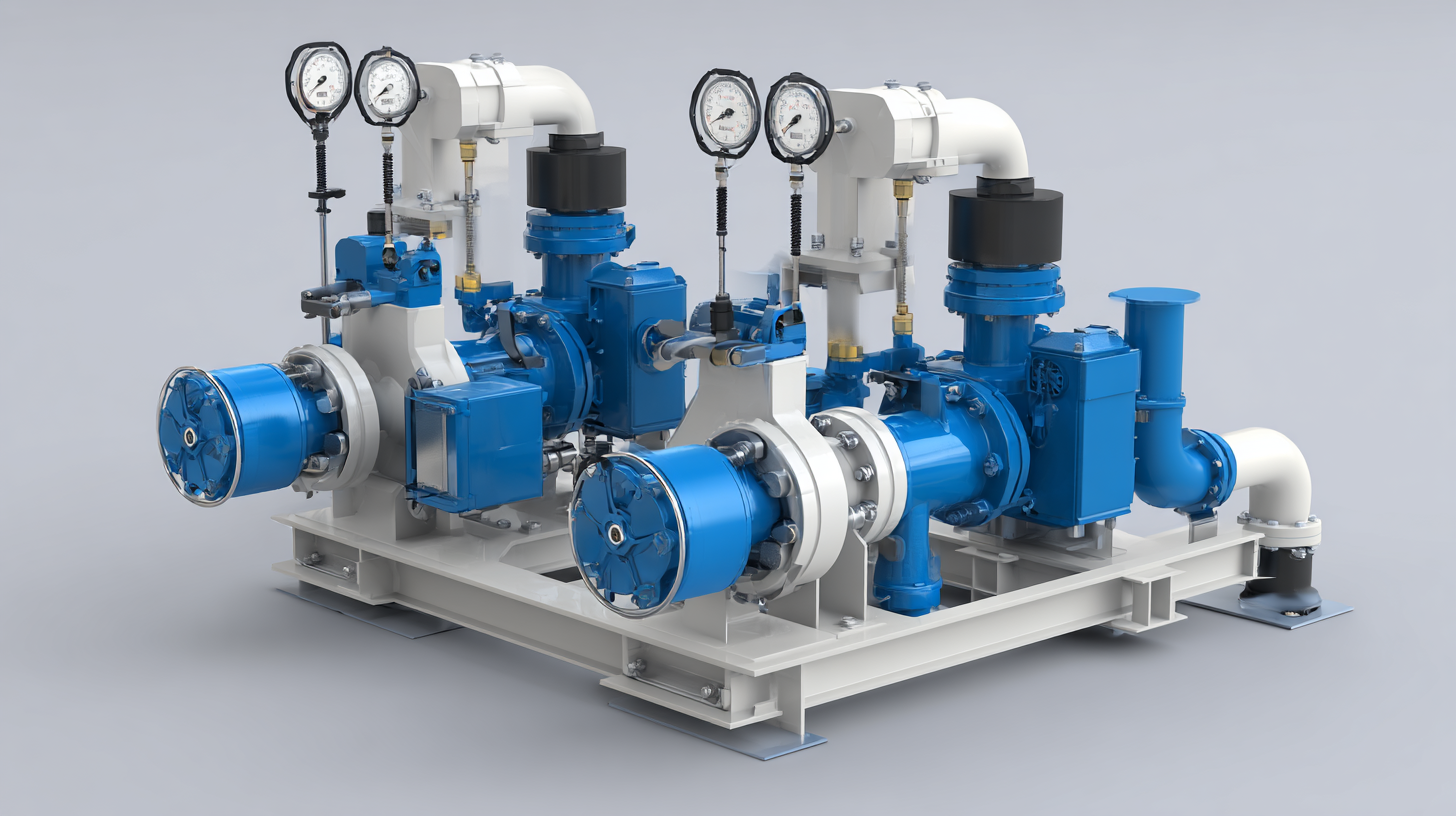

Impact of IoT Connectivity on Real-Time Data Analytics in Hydraulic Control

The integration of IoT connectivity into hydraulic control systems marks a significant evolution in modern engineering. By embedding sensors and devices within hydraulic machinery, engineers can collect vast amounts of real-time data regarding system performance, operational efficiency, and environmental conditions. This connectivity enables proactive monitoring, allowing for immediate adjustments to be made in response to detected anomalies or inefficiencies, ultimately leading to enhanced reliability and reduced downtime.

Furthermore, the impact of real-time data analytics cannot be overstated. With advanced analytics tools, engineers can process and analyze the data collected from hydraulic systems, identifying patterns and trends that were previously unobservable. This capability facilitates predictive maintenance, optimizing the lifecycle of hydraulic components and minimizing costly repairs. As a result, organizations can achieve higher operational efficiency, reduce energy consumption, and enhance overall productivity, positioning themselves at the forefront of innovation in hydraulic engineering. The symbiosis of IoT connectivity and hydraulic control represents a transformative shift, setting the stage for a smarter, more responsive infrastructure.

Advancements in Electro-Hydraulic Systems: Efficiency and Sustainability Metrics

Electro-hydraulic systems are revolutionizing modern engineering by enhancing the efficiency and sustainability of hydraulic control systems. These systems leverage the integration of electronic controls with hydraulic actuators, enabling precise manipulation of fluid dynamics while optimizing energy consumption. Recent advancements in sensor technology and control algorithms allow for real-time monitoring and adjustment, significantly reducing energy waste. As a result, electro-hydraulic systems become not only more efficient but also capable of minimizing their environmental footprint, addressing the growing demand for sustainable engineering solutions.

In addition to efficiency gains, the sustainability metrics associated with electro-hydraulic systems are gaining traction across various industries. By utilizing renewable energy sources and implementing adaptive control strategies, these systems demonstrate a commitment to reducing greenhouse gas emissions. Moreover, the durability and lower maintenance requirements of modern electro-hydraulic components contribute to their long-term sustainability, as they reduce the need for frequent replacements and resource-intensive repairs. The focus on combining efficiency with eco-friendliness positions electro-hydraulic systems at the forefront of sustainable engineering practices, essential for addressing the challenges of the future.

Advancements in Electro-Hydraulic Systems: Efficiency and Sustainability Metrics

Integration of AI in Hydraulic Control Systems for Enhanced Decision Making

The integration of artificial intelligence (AI) into hydraulic control systems is revolutionizing decision-making processes in modern engineering. Recent studies, such as those employing deep reinforcement learning techniques, illustrate how AI methods like the Deep Deterministic Policy Gradient (DDPG) algorithm can enhance traditional PID control strategies in hydraulic servo systems. This adaptive approach significantly improves the performance and responsiveness of systems, specifically in applications like injection molding machines, where precision and efficiency are crucial.

Moreover, AI-driven model predictive control is proving instrumental in optimizing operations for liquefied petroleum gas (LPG) recovery. By utilizing integrated computational models and multivariate regression, organizations can better balance operational efficiency with process stability, addressing common challenges in energy recovery systems. Reports indicate that the mining industry, notably through ERP systems, is experiencing a trend where hydraulic innovations and AI technologies significantly boost efficiency and data-driven decision-making. As organizations leverage these advancements, the role of AI in hydraulic control systems will only expand, paving the way for smarter engineering solutions across various sectors.

Emerging Trends in Smart Hydraulic Systems: From Automation to Remote Management

The evolution of smart hydraulic systems is significantly reshaping the landscape of modern engineering. Central to this transformation is the integration of artificial intelligence (AI) and Internet of Things (IoT) technologies, which enhance operational intelligence and enable remote management capabilities. These advancements allow for real-time monitoring and data-driven decision-making, resulting in increased efficiency and reduced downtime in hydraulic operations. Furthermore, AI algorithms can optimize system performance by analyzing data patterns and predicting potential failures before they occur.

In addition to operational enhancements, sustainability has become a key focus within hydraulic system innovation. Emerging technologies are being developed to improve water treatment processes and promote decentralized infrastructure, which ensures reliable service while minimizing environmental impact. Additionally, the integration of smart technologies in flood prevention measures showcases the industry's commitment to addressing climate challenges. As hydraulic systems continue to evolve, these trends signal a promising future where efficiency, sustainability, and smart infrastructure can coexist harmoniously in modern engineering.

Related Posts

-

Crafted in China's Leading Factory: The Trusted Excellence of Best Hydraulic Control Worldwide

-

The Ultimate Guide to Selecting the Best Control Hydraulic Systems for Your Global Procurement Needs

-

Ultimate Checklist for Choosing the Right Automatic Valves for Your Industrial Needs

-

Premium Quality Air Control Valves: Leading Global Exports from China

-

Discover Innovative Control Valve Types at the Upcoming Canton Fair in Guangzhou

-

Finding Top Suppliers for Best Valve Models with Industry Insights and Data